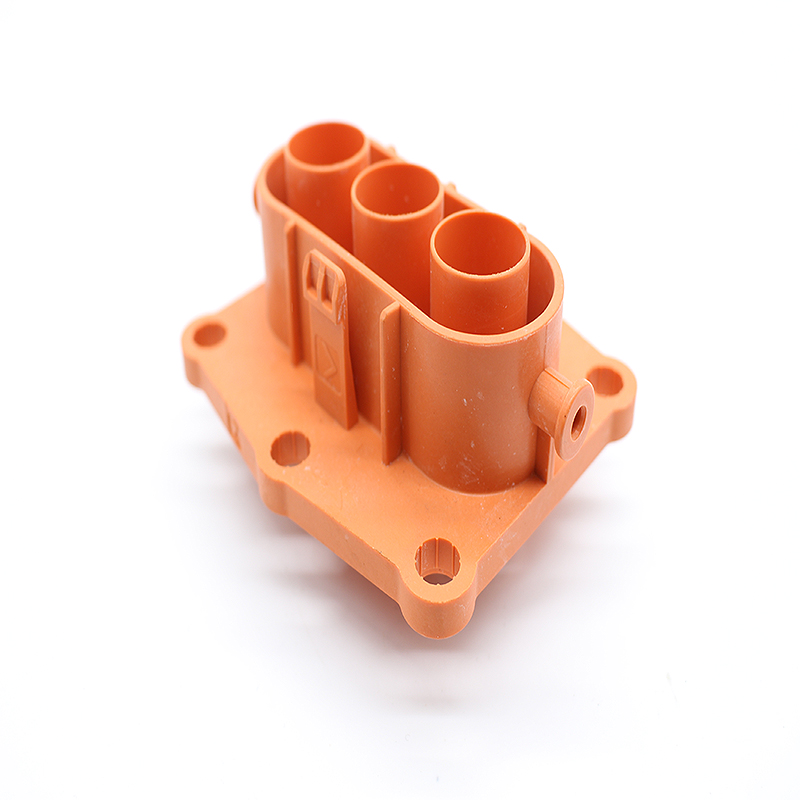

Customized plastic injection molding for ABS/PC Cosmetic Box

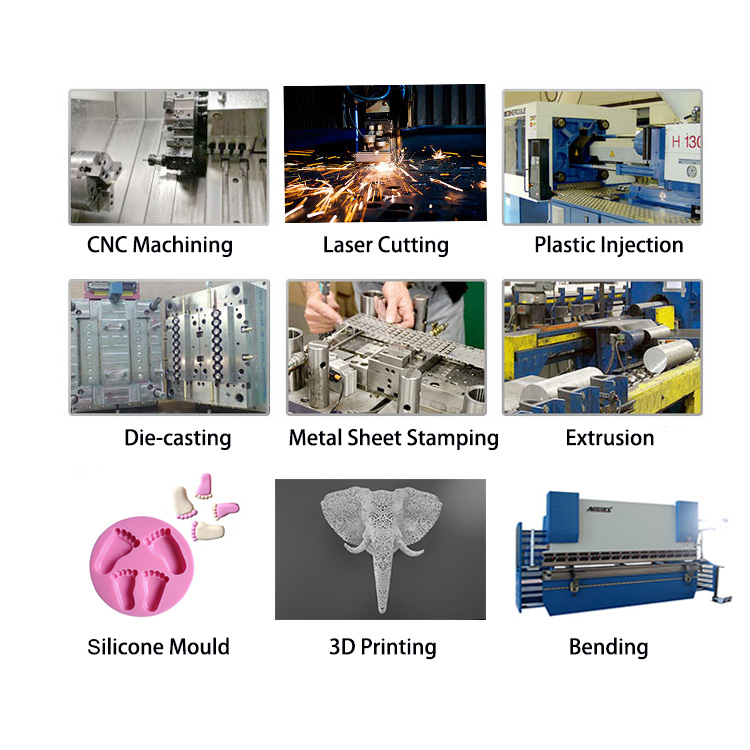

Attention:Please do not pay before we quote to you. The picture and prices shown are just for exhibition and display of our production. So please feel free to send us 3D drawing like STL/IGS/STP file and your product description. We have the magic to turn it into real products and then we will quote to …

Customized plastic injection molding for ABS/PC Cosmetic Box Read More »