Our Services

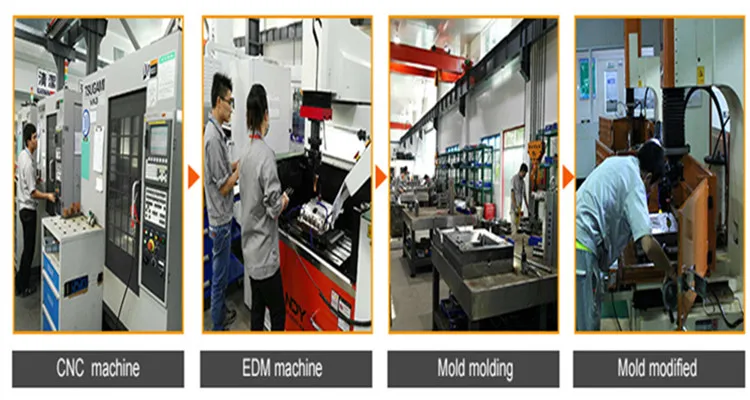

1. High precision deep hole drilling machine, EDM machine, wire-cutting machine, milling, grinding, auto punching machine, carving machine, 800tons to 1000tons high precision plastic injection molding machine etc advanced equipments.

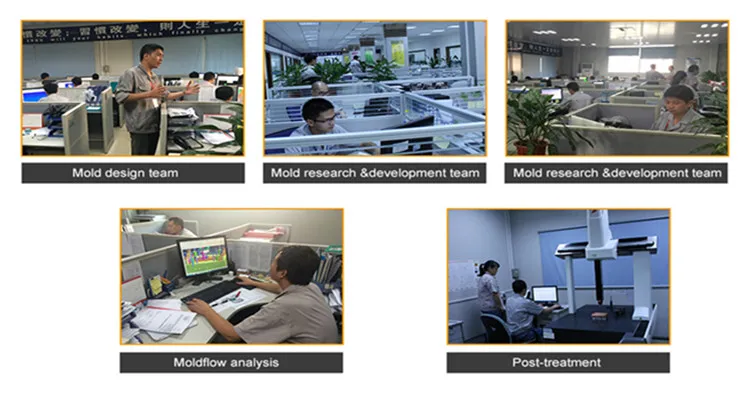

2. 20 Professional engineers 15 Pro-ID & MD 15 Pro-Moldflow analysis 40 skilled technicians 10 QC technicians.

3. Tooling workshop. From design control, steel hardness inspection, electrode inspection, core and cavity steel dimension inspection, pre-mould installtion inspection, trial report and sample inspection,export package inspection and ISO certification etc mould quality control process, Strictly QC process to control the quantity of the mold manufacture & final mould qualification.

Post-treatment workshop. Advanced equipment is to carry out the component finishing post-treatment processing.

4. Assembly workshop. 10+ advanced assembly lines and experienced engineers &operators control every detail from packing to final loading and on-time delivery.

5. Plastic injection molding parts tested workshop.

Company Information

Smart Mold technology,established in 1995,has been always devoting to plastic injection mold &plastic parts etc high precision mold design &manufacture over past 20 years.During this period,has cooperated with well-known enterprises,fg,VIVO Motorola Foxconn TCL Philips ZTE Littefuse Grammer Parrot Unikia Cardo etc.

Now,factory equipments further upgraded,workers continuously increase,Plastic Injection molding/moulding,plastic injection mold/mould,silicone molding, punching mould, die casting mold, stamping mold, rapid prototyping,IML/IMD process,hot/cold runner mold,double injection mold,2 shots molding,three-platemold,overmoldingetc a variety of molds can be design&manufactured.

Contact information

Certifications

What Customers Say

Why Choose Us