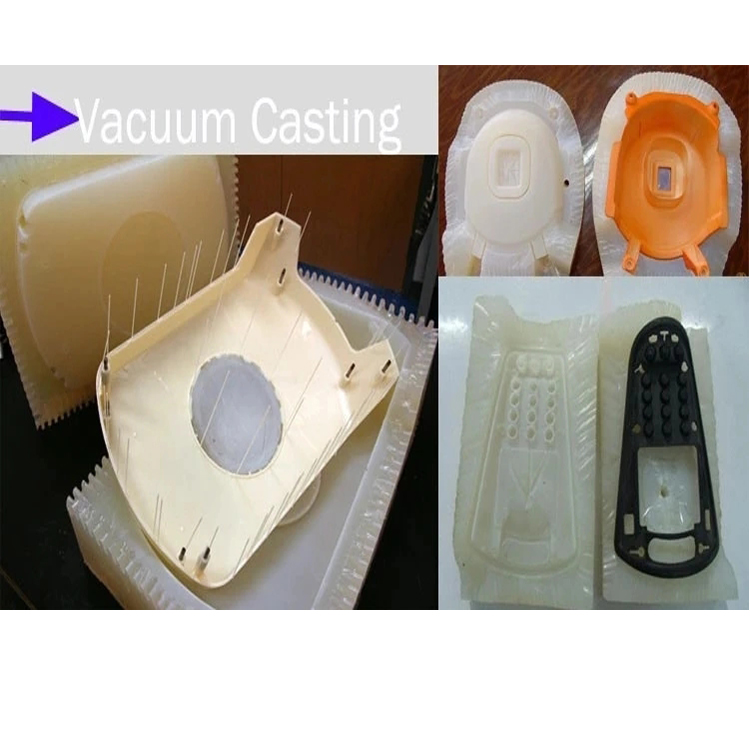

SILICONE MOLDING

With our in house capability of scanning and 3D printing technologies we start from the product then by processing vacuum silicone technology we achieve silicone mold. Also by vacuum casting models can be produce in low quantity for pre production. For this purpose the enginering materials to be used are, polyurethane, nylon, are polymers such as silicone rubber.

| Material | ABS, PC, PP, PA ,Silicone rubber, soft rubber, PC, acrylic etc |

| Dimension | as per your drawing |

| Surface treatment | Polishing, Painting,Plating, Anodizing,Hard anodizing, Brushing, Silk screen, Water Transfer,Laser engrave, Sandblasting, Gilding, Powder coating, Pad printing etc. |

| Lead Time | 7-10 days |

| Certificate | Material SGS files available |

| Tolerance | ±0.01mm to ±0.05mm, up to your requirement detail |