Smart Mold technology,established in 1995,has been always devoting to plastic injection mold &plastic parts etc high precision mold design &manufacture over past 20 years. During this period,has cooperated with well-known enterprises,fg,Legrand ,VIVO, Motorola ,Foxconn, TCL, ,Philips, ZTE ,Littefuse etc.

Now,factory equipments further upgraded,workers continuously increase,Plastic Injection molding/moulding,plastic injection mold/mould,silicone molding,punching mould,die casting mold,stamping mold, rapid prototyping,IML/IMD process,hot/cold runner mold,double injection mold,2 shots molding,three-plate mold,over molding etc avariety of molds can be design&manufactured.

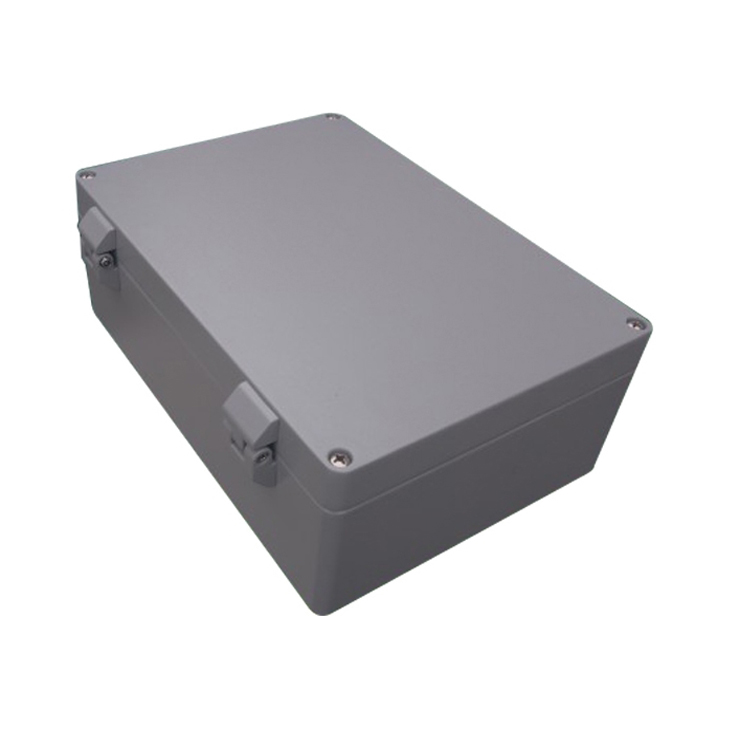

| Product type | Aluminum Rapid Prototyping Part |

| Service | CNC Machining, CNC Milling, CNC Turning |

| Business Type | Manufacturer,Trader |

| Processing | CNC machining, CNC milling and turning, laser cutting,drilling, grinding |

| Material | Aluminum:2024/5052/6061-T6/6063/6082/7075… Stainless Steel: 304/303/316/420/430… Steel 1214L/1215/1045/4140/SCM440/40CrMo/… Titanium: TC4/Gr2/Gr5… Plastic:POM/Acetal/Delrin/PEEK/ABS/Nylon/PTFE/Acrylic/PP/PC Brass 3602 / 2604 / H59 / H62 / …Bronze/Aluminum Bronze |

| Surface finish | polishing/ brush/ sand blasting, Normal anodize/harden anodize, black oxide, plating(Chrome/Nickel/zinc/gold/silver…)… |

| Tolerance | tight tolerances down to +/- .0001” (+/2.5 µm) and diameters from .145” (5 mm) to 2.5” (65 mm). in length |

Automotive part

home appliances part

Please feel free contact me Jessica sales7@smartmoldtech.com