Contact: Lily; Email address: sales2@smartmoldtech.com

SMART TECH was founded in 1995 and located in the national High-tech zone SongShan Lake industrial park, DongGuan, nearby Huawei. It covers 10000m²and we have 150 employees. Over last 20 years, we have supplied services for many clients such as Legrand(USA), Intel(USA), Motorola(USA), PDI(USA), Littefuse(USA), Grammer(Germany), Parrot(France),Unikia(Norway), Cardo(Israel), etc. all over the world. SMARTTECH is a leading manufacturer dedicated to mechanical engineering, CNC prototype, CNC machining, injection molding, aluminum/zinc alloy die casting, sheet-metal stamping, laser cutting and bending and finished product assembly. Our product cover the fields of auto parts, new energy battery parts, machinery parts, auto LED light and accessories, music stand and retail equipment, communications electronics product, medical equipment, industrial product, household appliance and fitness equipment etc.. We will provide you the best service with a good price, high quality product, shortest delivery time, as well as the economical engineering solutions. We passed the ISO9001:2018.The equipment of testing are: CMM, Quadratic measurement, projector, aging tester, salt spray tester, hardness tester, tension tester and IP5 waterproof test equipment.

| Brand name | SMART MOLD TECH |

| Mold shaping | Plastic Injection molding,Die Casting, Silicone molding,Punching mold,etc |

| Mold base | LKM;HASCO;DME,etc |

| Mold material | NAK20,S136,P20.718H,738H,45#,etc |

| Mold cavity | Single or Multi |

| Finish | Anodized,Polish,Silk-screen,Painting,etc |

| Sprue gate | Hot/cold runner;pin-point gate,etc |

| Design software | UG,PROE,CATIA,CAD,SOLIDWORK,etc |

| Product material | Metal,Aluminum,Rubber,Silicone, ABS,PP,PE,POM,PMMA,etc |

| Mold life | 100k-500k shots |

| Lead time | 25-45 days |

| Transportation | By sea, by air or by land as you request |

| Package | Standard or as you request |

| OEM/ODM | Acceptable |

Factory overview

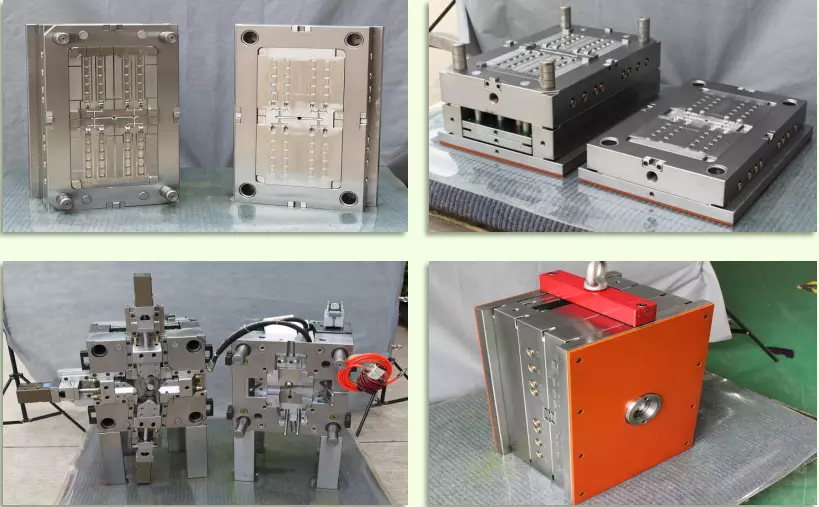

Mold workshop

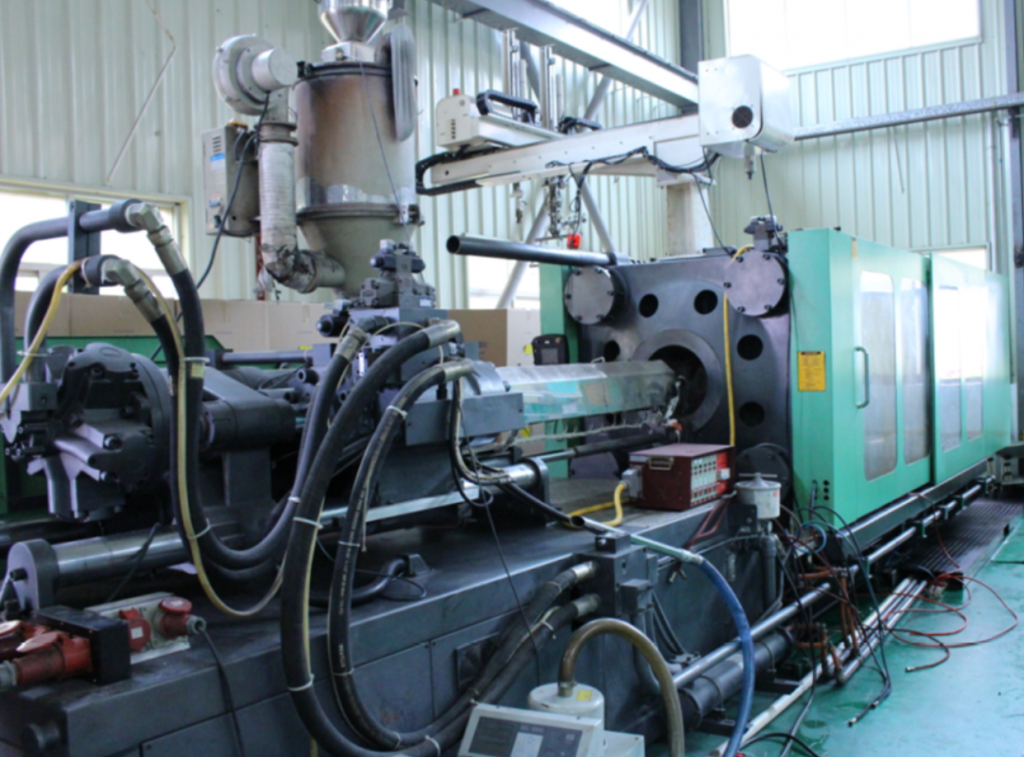

Injection molding machine

CNC Precision Machine

EDM Machine

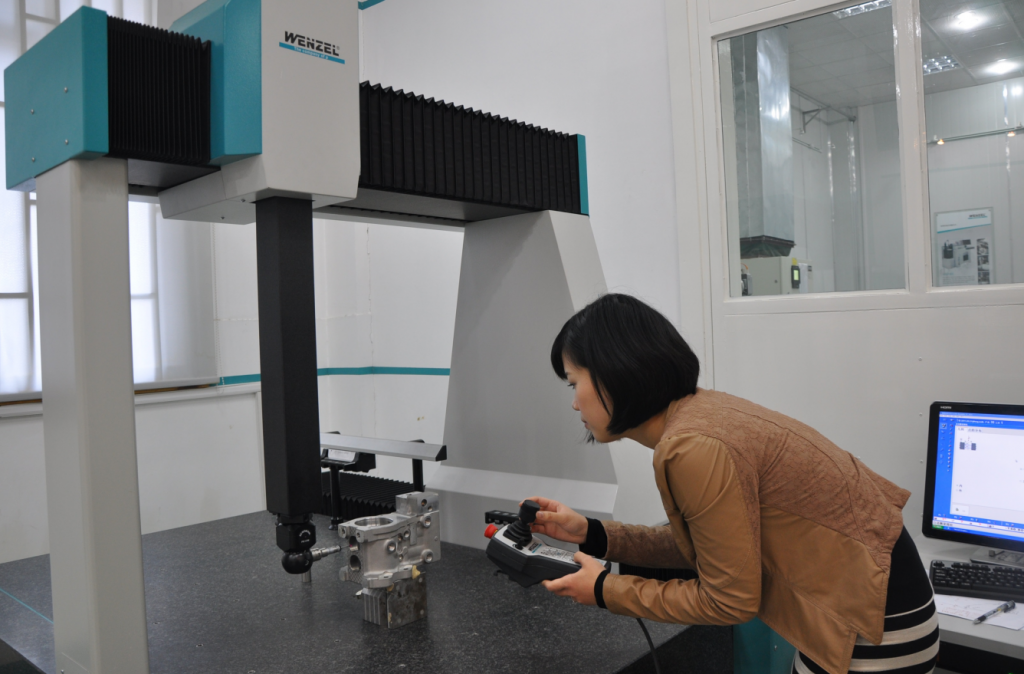

Inspection workshop

Finished plastic injection molds

Finished injection products

Quality Check

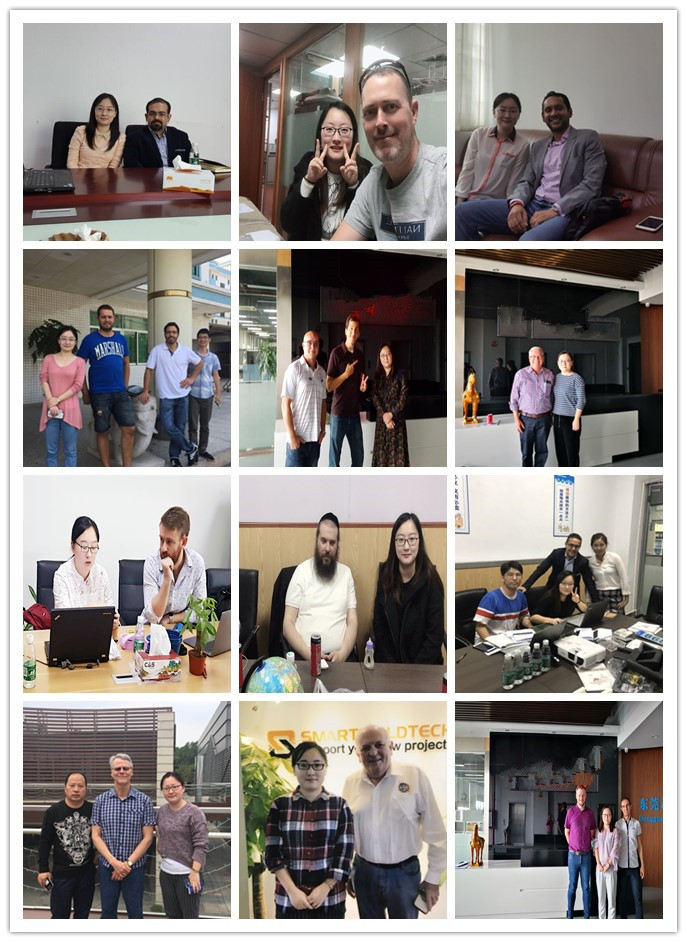

Customers cooperating with us and visit us

Our Services

Our company is a finish product design and prototype and plastic mold supplier in China,we have many clients from all the world,you please find the service as below from us.

1. Plastic mould and metal mold making,die casting mold

2. ID design and development

3. Prototype both metal and plastic.

4. Low volume assembly and design review.

5. Mass production for the injection molding.

6. Mechanical design and ID design.

7. Finish product assembly.

FAQ

Q. I have an idea for a new product, but not sure if it can be manufactured. Can you help with mold and injection molding?

A. Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up cost.

Q. My products have already been developed on CAD. Can you use the drawings?

A. Yes! X-P, STEP, IGES, X-T files can all be used to generate quotes of models and mould tools – this can save time and money in producing your plastic parts.

Q. Can I test my idea/product before committing to mould tool manufacture?

A. Yes, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q. What shall we do if we do not have drawings?

A. Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D STEP files will be made for you if placed order.

Q. What type of plastic is best for my design/product?

A. Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material for your new project.

Q. What type of mould tool do I need?

A. Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q. How long is the lead-time for mold?

A. It all depends on the mold’s size and complexity. Normally, the lead time is 4 weeks to finish a new mold.

Welcome your mail and messages for more questions, we will team work to support your new projects.

Contact: Lily; Email address: sales2smartmoldtech.com