| Part Material | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,…etc. |

| Size | According to your 2D, 3D Drawing |

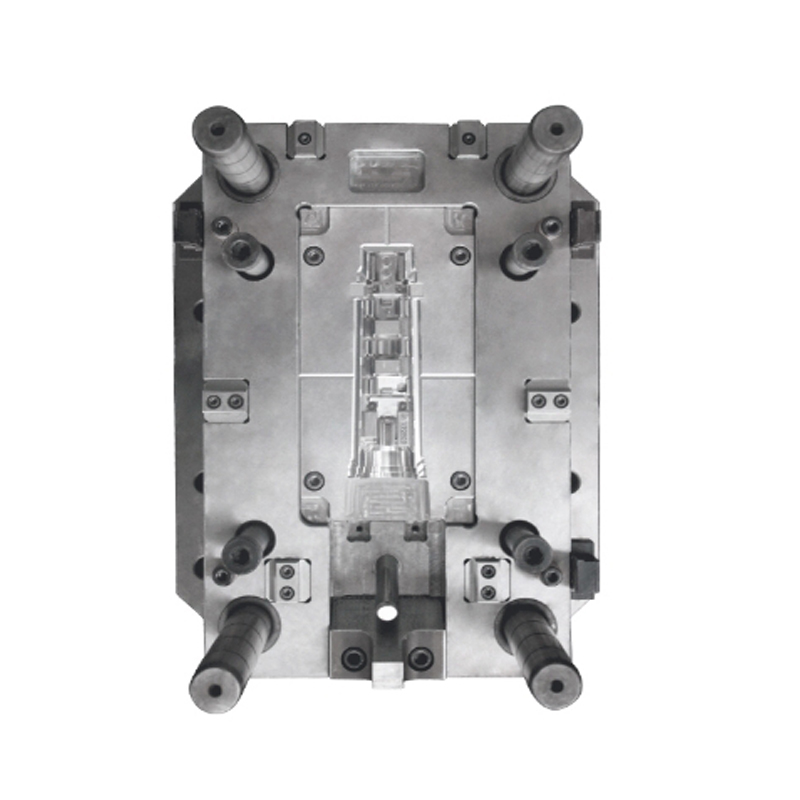

| Mould Cavity | Single or Multi Cavity, as your requirement |

| Cavity/Core Steel | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 …etc. |

| Mold Life | Depends on the steel hardness and the plastic material.Commonly used: 1. 100,000 ~ 500,000 shots or 1 year under normal use procedure for Pre-Hardness material. 2. 1,000,000 shots or 1 year under normal use procedure for Heat Treatment material. |

| Hardness of Cavity & Core | Pre-Hardness Steel: HRC 30 ~ 32 ± 1°Heat Treatment Steel: HRC 50~52± 1° |

| Runner system | Hot/cold runner |

| Mould Base Material | LKM, FUTA, HASCO, DME,…etc. Or as per Customer’s Requirment. |

| Surface treatment | Glossy, Matte, PVD,Chrome, Painting etc. |

| Leadtime | 4~7 weeks |

| Delivery term | FOB/CIF/EXWORKS |

| Equipments | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

| Mold Building Lead Time | T1, 4-5 weeks, Part measurement report (upon required). |

Packaging & Shipping

1.For mold: After assemble and clear mold, we paint anti-rust fog or grease on mold, then cover it with thin film and place it into a stable wooden box.

2.For plastic product: the first thing is to wrap each part up with semi-transparent thin foam and put it into plastic bag, the second step is place them into cartons with thin sponge plates to prevent scratches.

FAQ:

1. who are we?

We are based in Guangdong, China, start from 2015,sell to North America(00.00%),Western Europe(00.00%),Domestic Market(00.00%),Southern Europe(00.00%),Oceania(00.00%),Northern Europe(00.00%),South America(00.00%),Eastern Europe(00.00%),Mid East(50.00%),Central America(50.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Plastic Mold and Die Casting Mold

4. why should you buy from us not from other suppliers?

We can offer one-stop R&D services from engineering design, tooling , to custom injection molding, as well as 3D printing and assembly etc. Design for manufacturability and efficient production is our primary objective.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Japanese,German,French,Russian,Korean