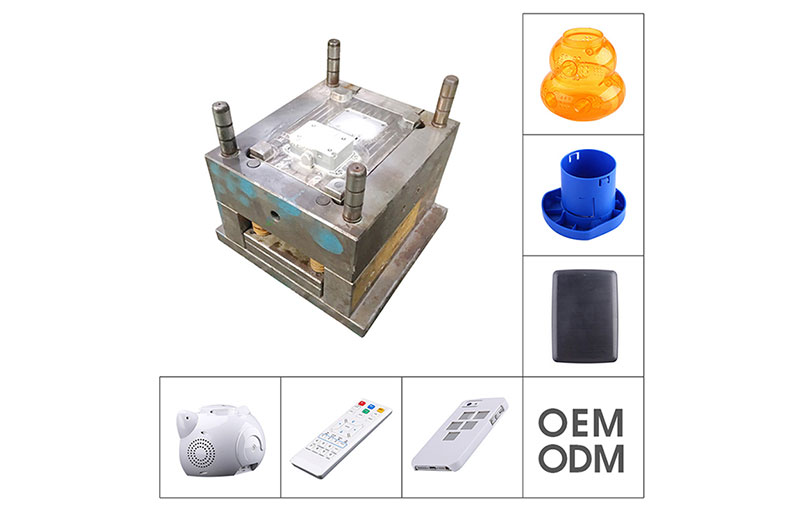

In the heart of the manufacturing industry lies a crucial process that enables the mass production of durable, precise, and cost-effective plastic components: Plastic Injection Mold Mass Production Molding. Our company is dedicated to this advanced technology, serving as a premier provider of high-quality injection molded parts for diverse industries ranging from automotive and electronics to healthcare and consumer goods.

Plastic Injection Molding is a manufacturing technique for producing parts by injecting material into a mold. The raw material, typically thermoplastic or thermosetting polymers, is fed into a heated barrel, mixed, and forced into a mold cavity under high pressure where it cools and hardens to the configuration of the cavity. This process allows for the creation of complex shapes with great detail and consistency, which is essential for products requiring tight tolerances and high precision.

Our commitment to excellence begins with our state-of-the-art facilities equipped with cutting-edge machinery capable of performing high-speed injection molding cycles. We maintain stringent quality control measures at every stage of production to ensure that each product meets our clients’ specifications and exceeds their expectations. Our team of skilled engineers utilizes the latest in CAD/CAM software to design molds that optimize efficiency and reduce waste, ensuring both environmental responsibility and economic viability.

We pride ourselves on our ability to deliver large volumes of products within short lead times without compromising on quality. By investing in automation and robotics, we have streamlined our operations to offer competitive pricing while maintaining the highest standards of craftsmanship. Moreover, our dedication to research and development keeps us at the forefront of innovation, allowing us to adapt quickly to market changes and emerging trends.

Sustainability is also a key focus for our business. We are continuously seeking ways to minimize our environmental footprint through the use of recycled materials and energy-efficient processes. As part of our corporate social responsibility, we adhere to strict environmental regulations and strive to promote sustainable practices within the industry.

At our company, we believe that success is built on partnerships. We work closely with our clients from concept to completion, providing comprehensive support services including design consultation, prototyping, testing, and post-production assistance. Through collaboration and trust, we aim to create value-added solutions that contribute to our partners’ success and growth.

In conclusion, our Plastic Injection Mold Mass Production Molding service is not just about manufacturing; it’s about delivering innovation, quality, and sustainability to our customers worldwide.