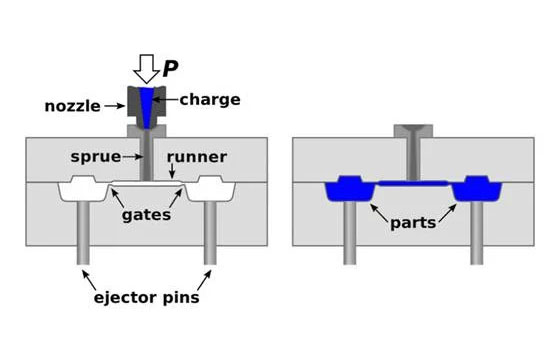

The working principles of injection molding are likened to syringes used for injection. The operator pours the raw material into the hopper through a feeding device, which goes down to the barrel heater, where the plastic resins are heated past their melting point to liquid. Afterward, a hydraulic ram, resembling a rotating screw, forcefully pushes the molten plastic, injecting it into the closed mold cavity.

This injection of the molten material continues at a high pressure of about 100 to 150 MPa until the mold cavity is filled. The content takes the mold’s shape, after which it begins to cool, solidifying to the desired shape and structure.

Then, the mold opens, using the ejectors to remove it carefully without exerting damage. At the same time, the mold closes for a repeat of the process until the desired volume of parts is injection molded. This process is fast, happening within seconds, supporting the production of thousands of parts per cycle.