1 Anodizing

It is an electrochemical method that improves the natural oxide layer on metals’ surfaces, most especially aluminum. Anodizing increases metal parts’ corrosion resistance, wear resistance, and surface hardness while allowing colored parts for aesthetic reasons.

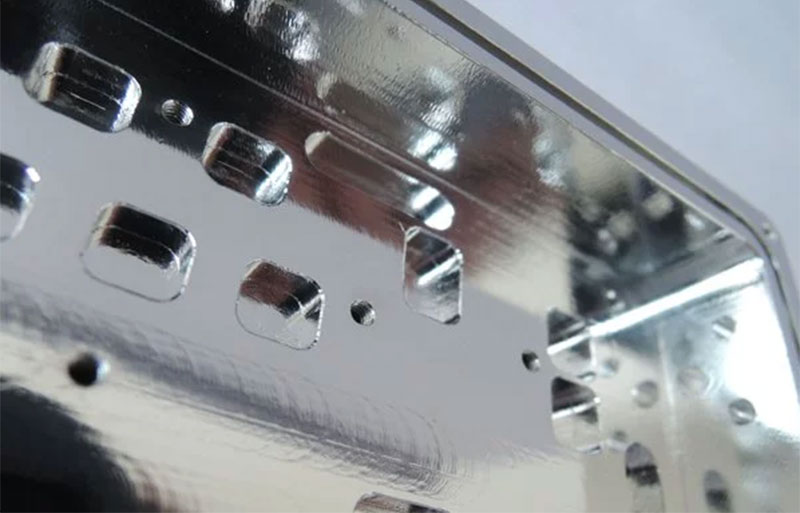

2 Electroplating

This custom surface finishing process allows the deposition of a metal coating on a part using an electric current. Electroplating helps to effectively control the thickness and composition of the deposited layer, enhancing electrical conductivity, aesthetic appeal, and corrosion resistance properties.

3 Electroless Nickel Plating

It is also called nickel phosphorous plating. It involves depositing an even layer of nickel-phosphorous alloy on the top surface of metals like steel or aluminum. The solid substrate is immersed in a water solution with nickel salts and phosphorous-reducing agents. Electroless nickel plating offers a uniform coating distribution, good adhesion, and corrosion resistance properties.

4 Electropolishing

Electropolishing is a standard electrochemical finishing method that dissolves the outer layer of materials to eliminate surface irregularities, providing a brighter and smoother surface. It improves the cleanability and corrosion resistance of metal parts.

5 Powder Coating

The powder coating method entails coating a solid substrate with free-flowing dry powder. The dry powder (thermoplastic or thermoset polymer) is sprayed electrostatically and cured at high temperatures under UV light or heat. This CNC metal finish works best with metal materials.