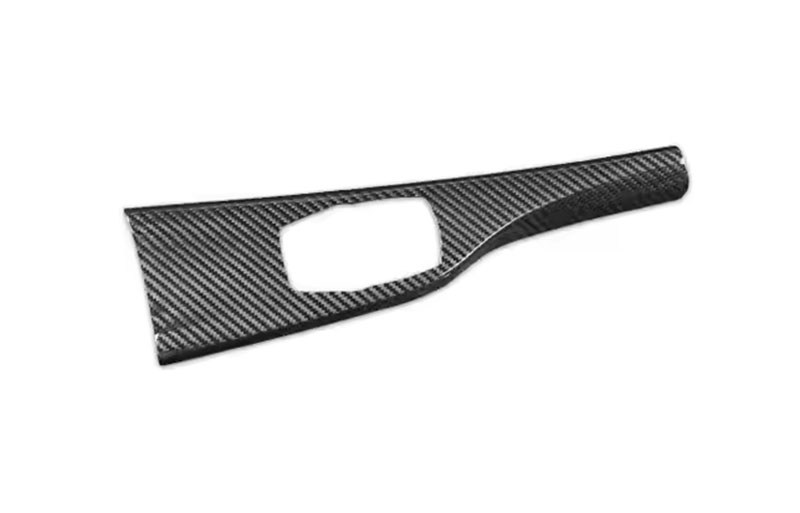

In the fast-evolving automotive industry, rapid tooling has become an indispensable process for accelerating product development cycles while ensuring high-quality standards. Our company specializes in providing advanced rapid tooling solutions specifically tailored for car dashboard covers. This service leverages cutting-edge technologies and materials to drastically reduce production time without compromising on the precision or durability of the final product.

Our rapid tooling process for car dashboard covers begins with a detailed design phase, where we collaborate closely with our clients to understand their exact requirements and specifications. Utilizing CAD software, we create precise digital models that serve as the foundation for the tooling process. Following this, we employ state-of-the-art CNC machines and 3D printing technologies to manufacture molds quickly and efficiently. These molds are then used in the injection molding process to produce high-quality dashboard covers that meet stringent automotive standards.

One of the key advantages of our rapid tooling service is its flexibility. We can accommodate a wide range of modifications and adjustments throughout the development process, allowing for iterative improvements based on client feedback. Additionally, our team of experts ensures that every dashboard cover produced not only looks impeccable but also integrates seamlessly with the vehicle’s interior design, enhancing both aesthetics and functionality.

Through our commitment to innovation and excellence, we have successfully supported numerous automotive manufacturers in bringing their products to market faster, making us a trusted partner in the industry.