Turning-milling compound machining is a manufacturing process that combines the advantages of turning and milling operations. This process involves the use of a single machine that can perform both turning and milling operations on a single workpiece. This method of machining is widely used in the production of complex parts that require high precision, accuracy, and repeatability.

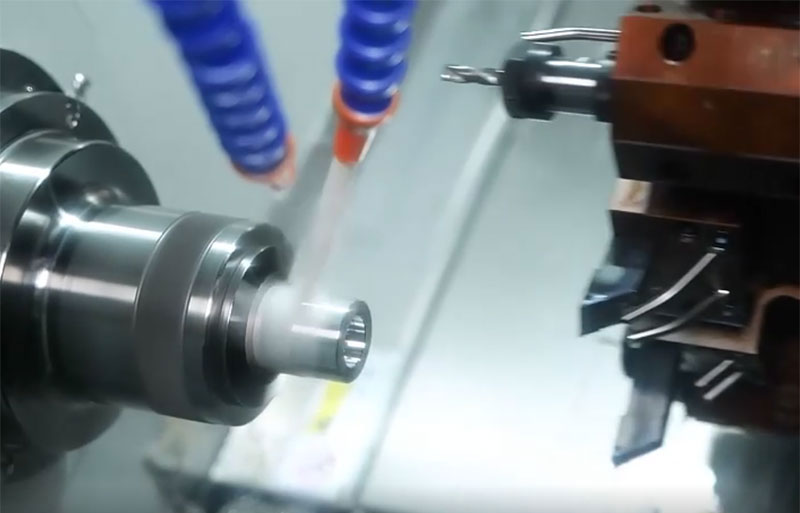

In turning-milling compound machining, the workpiece is held in place by a chuck or a fixture, while a cutting tool moves in two axes (X and Y) to remove material from the surface of the workpiece. The tool is rotated in a clockwise or counterclockwise direction, while the workpiece is rotated in the opposite direction.

The cutting tool can be either a milling cutter or a turning tool, depending on the requirements of the part. This process is suitable for the production of parts with complex geometries, such as gears, impellers, and turbine blades.