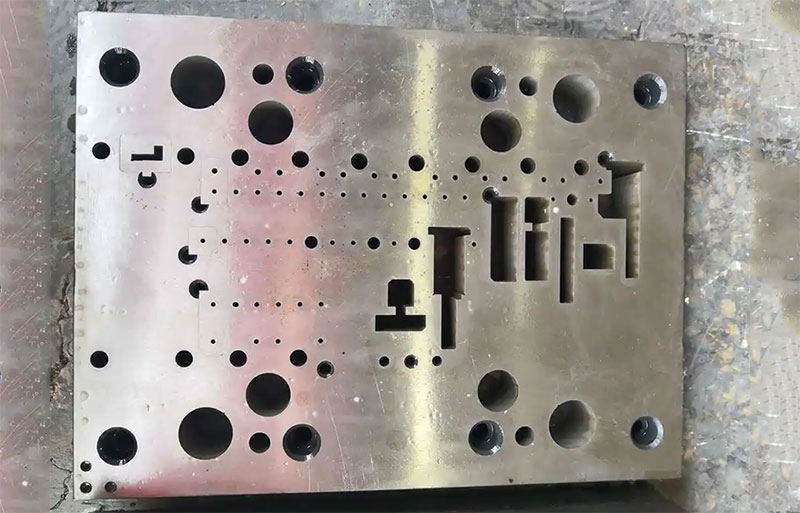

SMARTTECH specializes in Wire Electrical Discharge Machining (Wire EDM) for the rapid creation of molds, catering to the needs of the rapidly evolving manufacturing industry. With a focus on precision and efficiency, we leverage state-of-the-art Wire EDM technology to deliver high-quality molds in the shortest possible timeframe.

Wire EDM, also known as wire electrical erosion machining, is a non-contact machining process that uses a thin, continuously moving wire as an electrode to cut through conductive materials. This process allows for intricate and detailed cutting, making it ideal for the production of molds with complex geometries and tight tolerances.

Our team of experienced engineers and technicians utilizes advanced software to program and execute precise cuts, ensuring that each mold meets or exceeds the customer’s specifications. We offer a wide range of mold-making services, including prototype development, small-batch production, and large-scale manufacturing.

In addition to precision and efficiency, our Wire EDM process offers several other advantages. It produces minimal heat-affected zones, reducing the risk of material distortion or It damage. also allows for the machining of hard and difficult-to-cut materials, such as tool steels, carbides, and ceramics.

By choosing SMARTTECH for your rapid mold needs, you can expect a seamless process from design to delivery. We are committed to providing exceptional customer service, competitive pricing, and unmatched quality. Contact us today to learn more about our Wire EDM machining services for rapid mold production.